Warsaw Foundry Company, Inc.

Warsaw Foundry Company, Inc.Request A Quote

Warsaw, IN | 574-267-8772At Warsaw Foundry Company, we specialize in producing high-quality grey iron castings, serving a wide range of industries with precision-engineered components. Our expertise lies in delivering castings that meet the exact specifications of our customers, whether for complex industrial applications or high-volume production runs. With a commitment to excellence, we utilize advanced foundry techniques and stringent quality control processes to ensure durability, consistency, and superior performance in every casting we produce. Our capabilities extend to pattern design, mold making, and machining, allowing us to provide fully finished cast components that integrate seamlessly into our customers’ manufacturing processes. By leveraging state-of-the-art equipment and a highly skilled team, we offer customized solutions tailored to unique project requirements. Our experience in working with grey iron enables us to produce castings with exceptional strength, wear resistance, and dimensional accuracy, making them ideal for applications in heavy machinery, automotive, construction, and various other demanding industries. We take pride in our ability to deliver reliable, cost-effective casting solutions while maintaining the highest industry standards. Our customer-centric approach ensures that we work closely with each client to understand their needs and provide castings that enhance product performance and longevity. Whether fulfilling small custom orders or large-scale production demands, we remain dedicated to quality, precision, and innovation in grey iron casting manufacturing.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

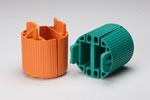

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services