Roloff Manufacturing Corporation

Roloff Manufacturing CorporationRequest A Quote

Kaukauna, WIAt Roloff Manufacturing, we specialize in producing high-quality grey iron castings, delivering durable and precise components for a variety of industries. Our expertise extends across the entire casting process, from pattern design and mold preparation to finishing and quality control. With a focus on consistency and reliability, we manufacture castings that meet stringent industry standards while accommodating custom specifications to fit unique applications. Our capabilities include advanced molding techniques and specialized finishing processes that enhance the strength, wear resistance, and dimensional accuracy of each casting. Whether producing standard parts or complex, custom-engineered components, we ensure superior metallurgical properties and casting integrity. Our commitment to innovation and continuous improvement allows us to refine our processes, optimize material efficiency, and maintain cost-effective production without compromising quality. We serve a wide range of industries, providing castings for applications in machinery, construction, transportation, and beyond. Our facility is equipped with modern foundry technology, allowing us to handle projects of varying scales with precision and efficiency. Through rigorous testing and quality assurance, we guarantee that every casting leaving our facility meets the highest performance standards. Customer satisfaction remains at the core of our operations, and we collaborate closely with clients to develop solutions tailored to their exact needs. By combining decades of experience with advanced manufacturing capabilities, we continue to be a trusted partner for companies seeking durable, high-performance grey iron castings.

Leading Grey Iron Casting Companies

More Grey Iron Casting Companies

Additional Categories: Air Compressors, Air Pollution Control, Aluminum Extrusions

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

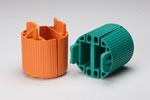

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services