Illini Foundry Company

Illini Foundry CompanyRequest A Quote

Peoria, IL | 309-697-3142https://www.illinifoundry.com/

At Illini Foundry Company, we specialize in producing high-quality grey iron castings, serving a diverse range of industries with precision-engineered solutions. With a commitment to excellence, we utilize advanced foundry techniques to deliver durable and reliable cast components that meet the rigorous demands of our customers. Our expertise extends to a variety of casting sizes and complexities, ensuring that we can accommodate both standard and custom requirements. Through state-of-the-art molding and melting processes, we achieve consistent quality and superior metallurgical properties in every casting. Our capabilities include pattern design, tooling development, and finishing services, allowing us to provide fully machined and ready-to-use components. We work closely with our customers to develop tailored solutions, optimizing casting designs for performance, efficiency, and cost-effectiveness.

With a focus on quality assurance, we implement stringent testing and inspection procedures to ensure that each casting meets industry standards and customer specifications. Our team is dedicated to maintaining short lead times and dependable delivery schedules, providing responsive service to support a variety of production needs. By combining decades of foundry experience with modern technology, we continue to be a trusted partner for grey iron castings in applications ranging from industrial machinery to infrastructure and beyond.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

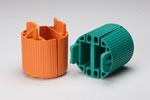

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services