Dakota Foundry

Dakota FoundryRequest A Quote

Webster, SD | 605-345-3349We specialize in producing high-quality grey iron castings at Dakota Foundry, offering durable and precision-crafted components to meet the needs of various industries. With our advanced foundry capabilities, we take pride in delivering castings that meet exact specifications while maintaining the highest standards of quality and performance. Our expertise in pattern making, molding, and finishing allows us to create custom solutions that align with the specific requirements of our customers. Using state-of-the-art technology, we manufacture castings in a wide range of sizes and complexities, ensuring consistency and reliability in every piece we produce. Our commitment to innovation and efficiency drives us to refine our processes, providing cost-effective and high-performance castings that exceed industry expectations. We offer a comprehensive approach to casting production, incorporating machining and finishing services to deliver turnkey solutions that streamline the supply chain for our customers. By leveraging decades of experience and a deep understanding of metallurgy, we optimize the properties of grey iron to enhance strength, wear resistance, and machinability. Our team of skilled professionals is dedicated to delivering superior craftsmanship, ensuring that every casting we produce meets the rigorous demands of modern applications. Whether serving the agricultural, automotive, industrial, or heavy equipment sectors, we remain focused on providing castings that stand the test of time. Customer satisfaction remains at the core of our operations, driving us to maintain stringent quality control measures throughout the entire production process. With a strong commitment to excellence, reliability, and customer-focused service, we continue to be a trusted partner in the grey iron casting industry.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

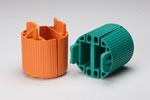

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services