buckcompany

An iron casting is a hard product obtained from combining iron with carbon. This can be readily cast in a mold, and it contains a higher proportion of carbon compared to steel. The proportion typically ranges from 2 to 4.3...

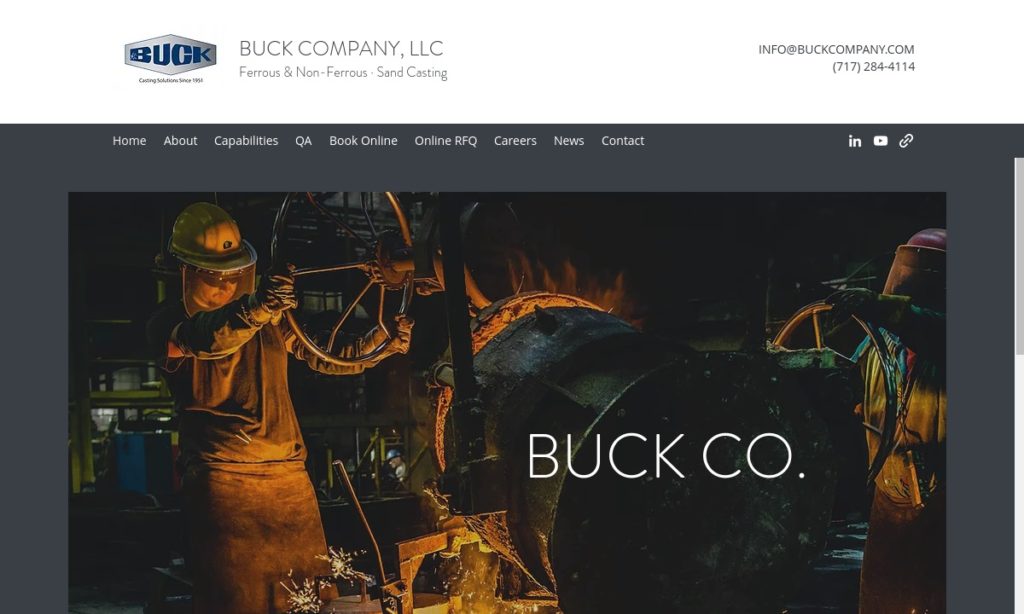

The casting process is an ancient art that goes back several thousand years to the beginning of written history. The archeological record has finds that document the use of the casting process over 6000 years ago around 3000 BC or BCE...

Sand casting is a manufacturing process in which liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then allowed to solidify. Casting is a manufacturing process in which...

Forging is a metal working process that manipulates, shapes, deforms, and compresses metal to achieve a desired form, configuration, or appearance outlined by a metal processing design or diagram. Depending on the type of metal and the...

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts with a high quality finish. Its ability to produce detailed parts makes it perfect for the mass production of products...

Investment casting is a metal working process that uses a ceramic shell built over a wax pattern to produce parts with extraordinarily uniform and smooth surfaces. The wax pattern is produced from an aluminum die.The final products of investment casting are without parting lines, mold half marks, or other deformities...