Associated MetalCast

Associated MetalCastRequest A Quote

Oxford, AL | 256-831-8000https://www.associatedmetalcast.com/

At Associated MetalCast, we specialize in the art and science of investment castings, delivering precision-engineered solutions that meet the diverse needs of our clients across various industries. Our commitment to quality is evident in every aspect of our operations, from the meticulous selection of high-grade materials to our advanced casting techniques. We pride ourselves on our ability to produce intricate and complex shapes that traditional manufacturing processes cannot achieve. Our state-of-the-art facilities are equipped with the latest technology, allowing us to create high-precision components with exceptional surface finishes and tight tolerances. Our team of skilled professionals brings a wealth of expertise to the table, ensuring that each project is executed with the utmost care and attention to detail. In addition to our core investment casting capabilities, we offer a comprehensive range of services that include design assistance, prototyping, and post-casting operations such as machining and finishing. We work closely with our clients to understand their specific requirements, providing tailored solutions that enhance performance and reduce production costs. Our collaborative approach fosters long-term partnerships, as we strive to be not just a supplier but a trusted partner in our clients' success. We are dedicated to continuous improvement and innovation, constantly seeking new ways to enhance our processes and expand our capabilities. Our commitment to sustainability is reflected in our efforts to minimize waste and maximize efficiency throughout our operations. At Associated MetalCast, we stand ready to tackle the challenges of today's manufacturing landscape, delivering exceptional investment castings that exceed expectations and drive success for our clients.

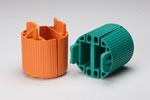

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services